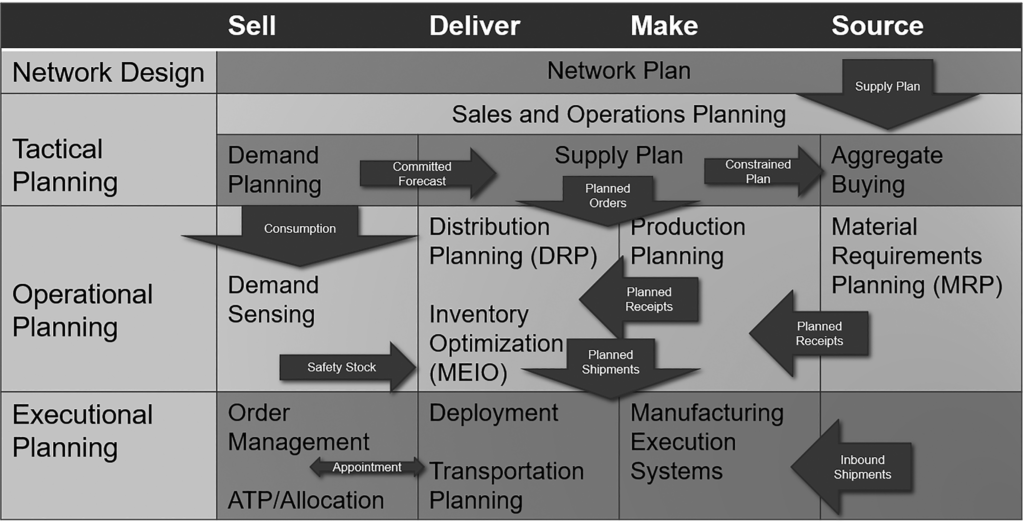

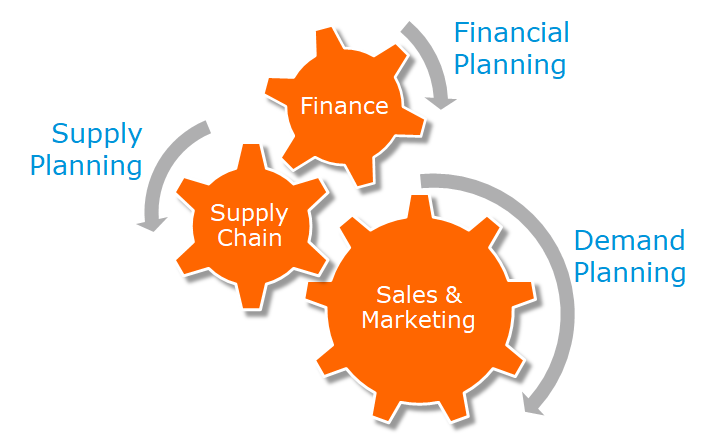

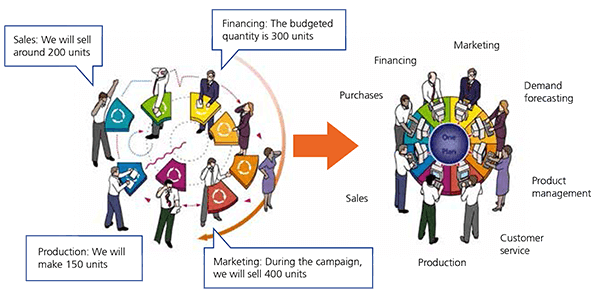

The sales and operations planning (S&OP) process is critical to supply chain optimization, but tough to get right Too often there's a disconnect between high level aggregate business plans and detailed operation execution plans ToolsGroup S&OP software provides a single integrated data model to enable collaboration and optimization With this single version of the truth, you canA budget review S&OP is based on current inputs concerning demand and supply;S&OP is successful because it aligns planning across functions in order to meet company objectives and improve performance Compromise is often required between functional areas and, at times, functional leaders may disagree on the best approach The executive S&OP meeting provides a forum for routine decisionmaking where the executive leader considers team

Sales And Operations Planning S Op Logistiikan Maailma

So planning

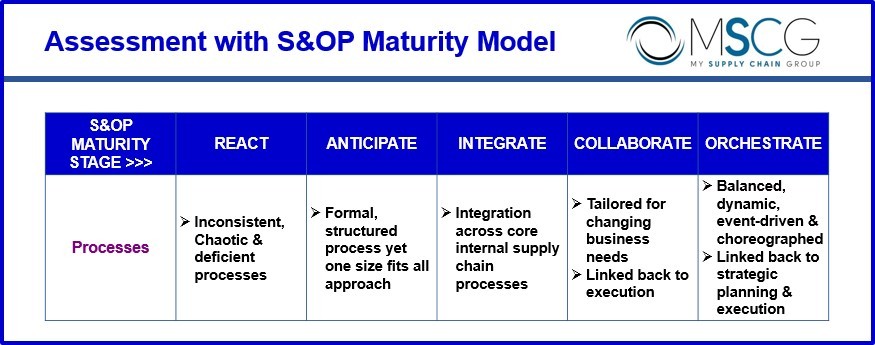

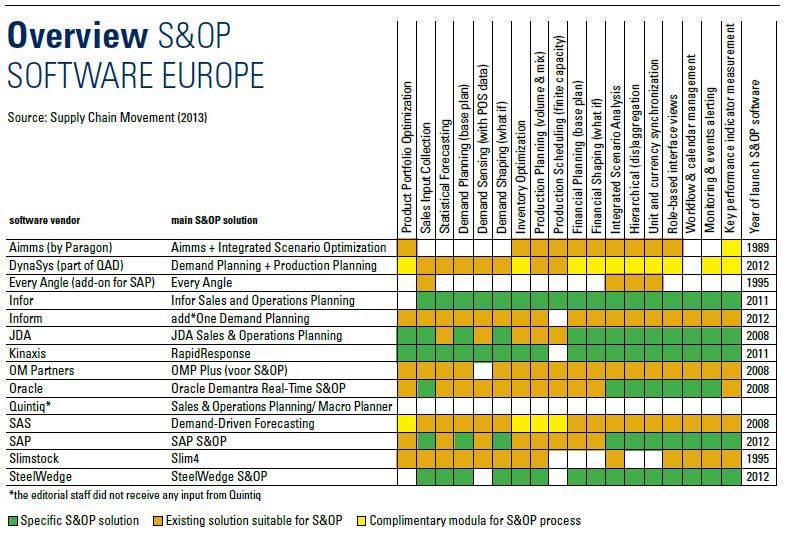

So planning-A sales and operations planning (S&OP) system of differentiation (SOD) is a software solution that supports a Stage 4 or highermaturity S&OP process It may do this in conjunction with other supply chain planning (SCP) SODs (such as supply chain modeling, multienterprise inventory optimization and demand sensing), and with the support of a foundational SCP system of record (SOR)Integrated planning Perfect integration of S&OP and operational planning Unison Planning™ based on one data model and planning solution ensures flawless bidirectional communication between S&OP and all other planning functions

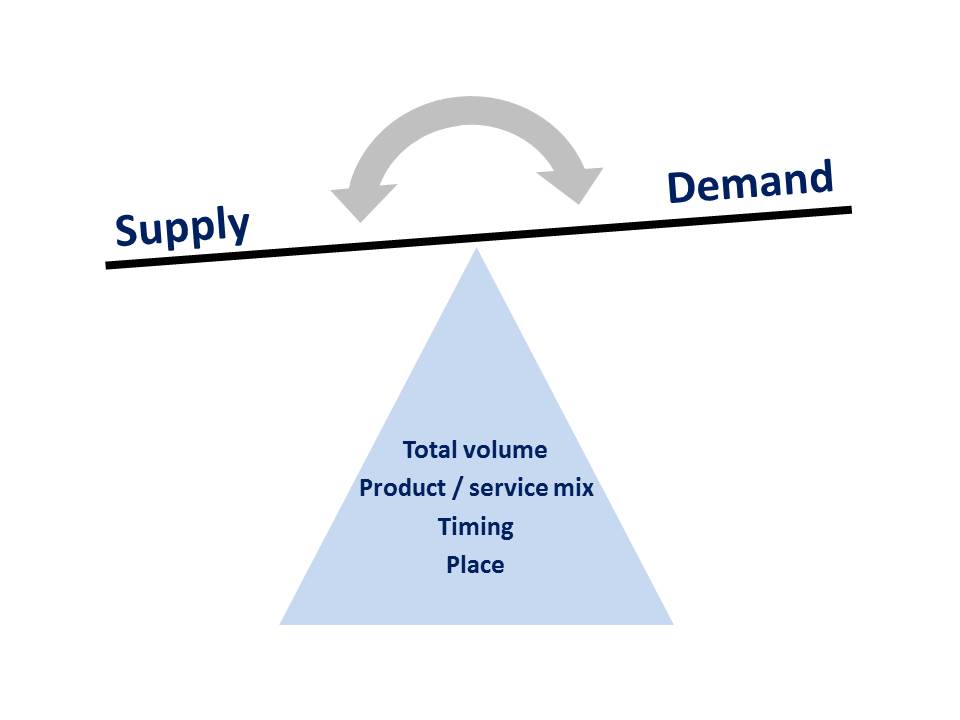

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

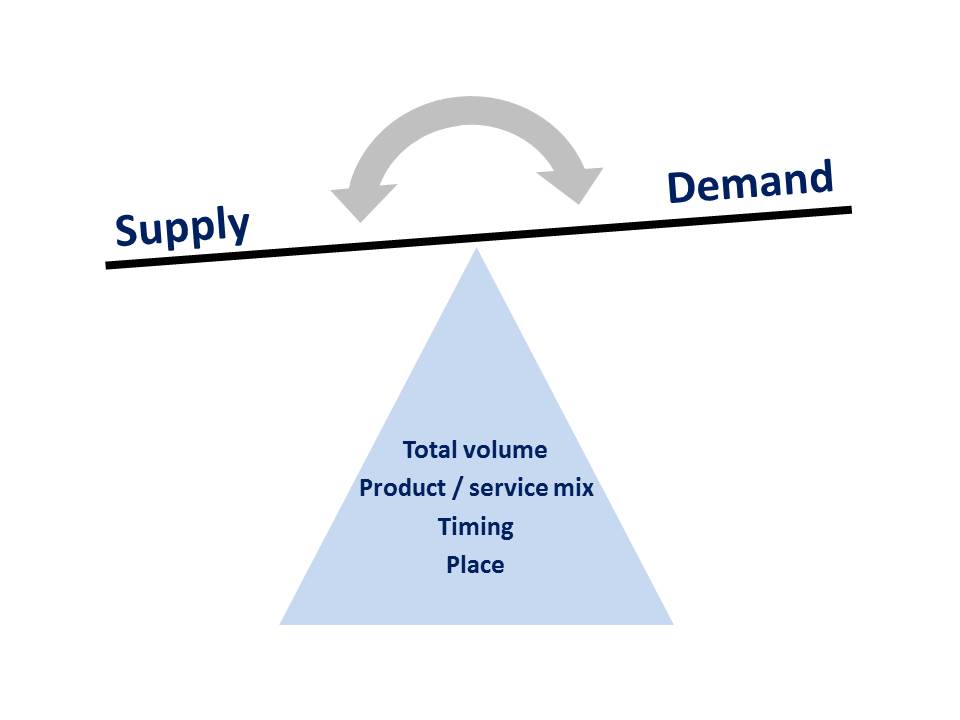

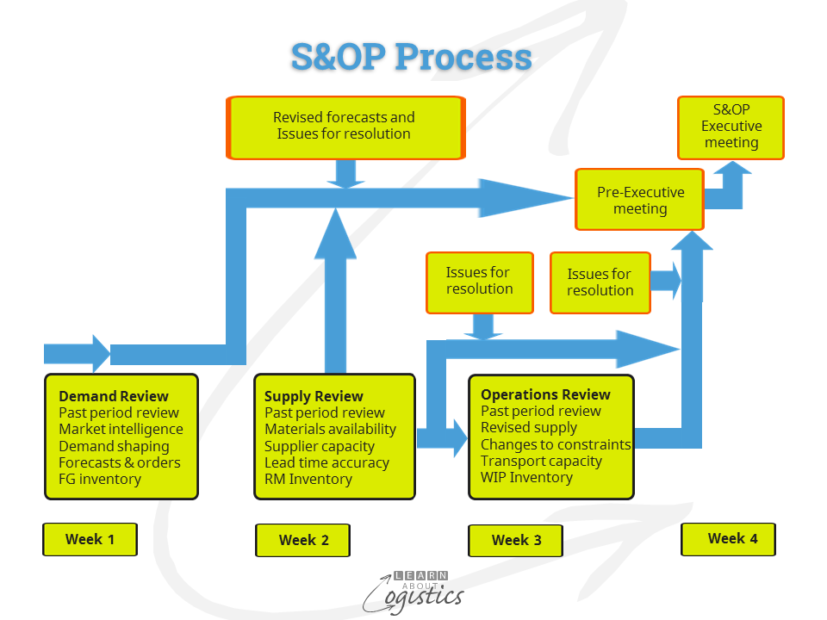

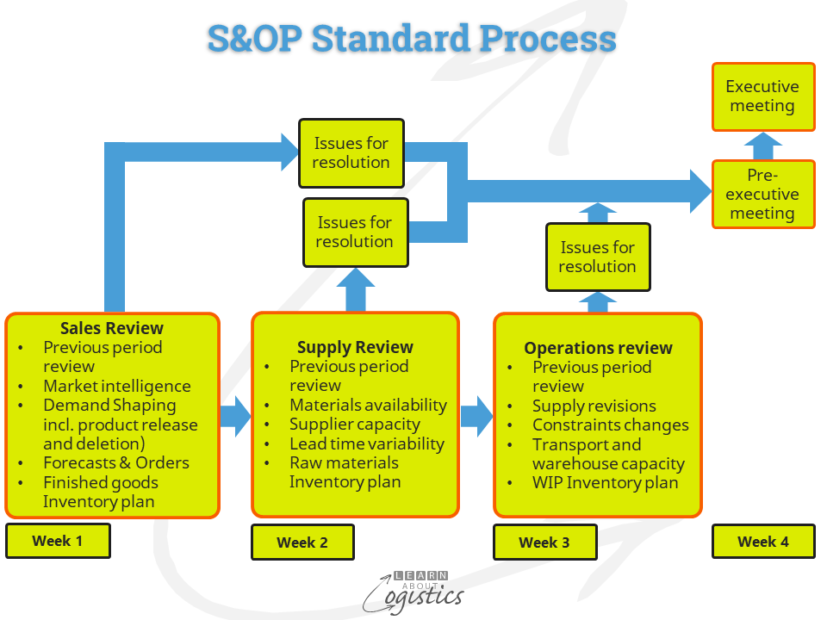

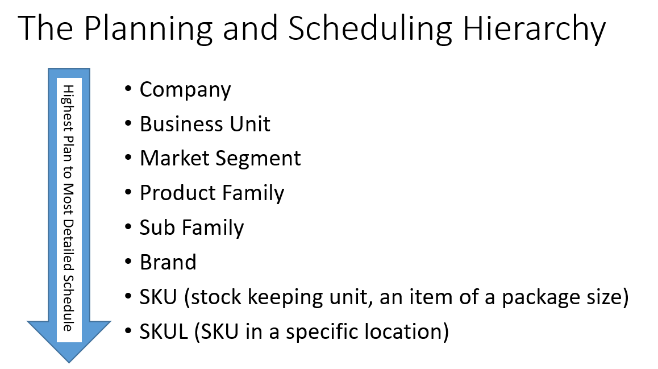

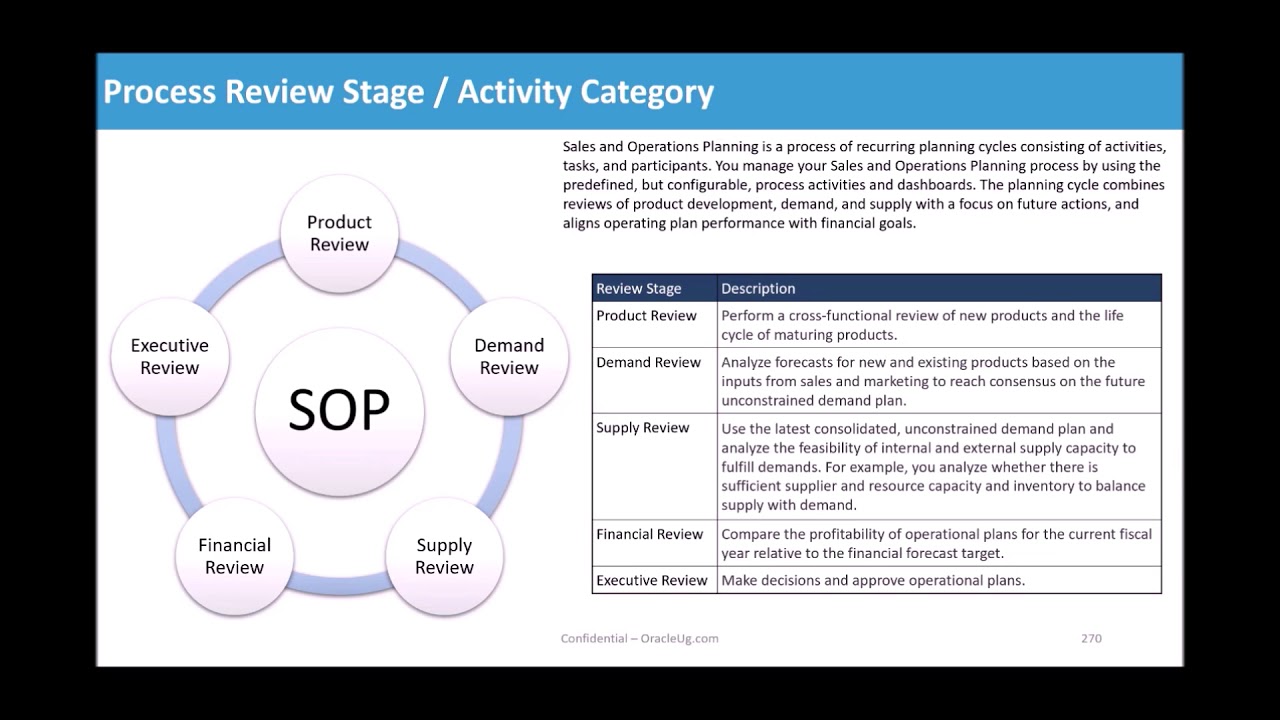

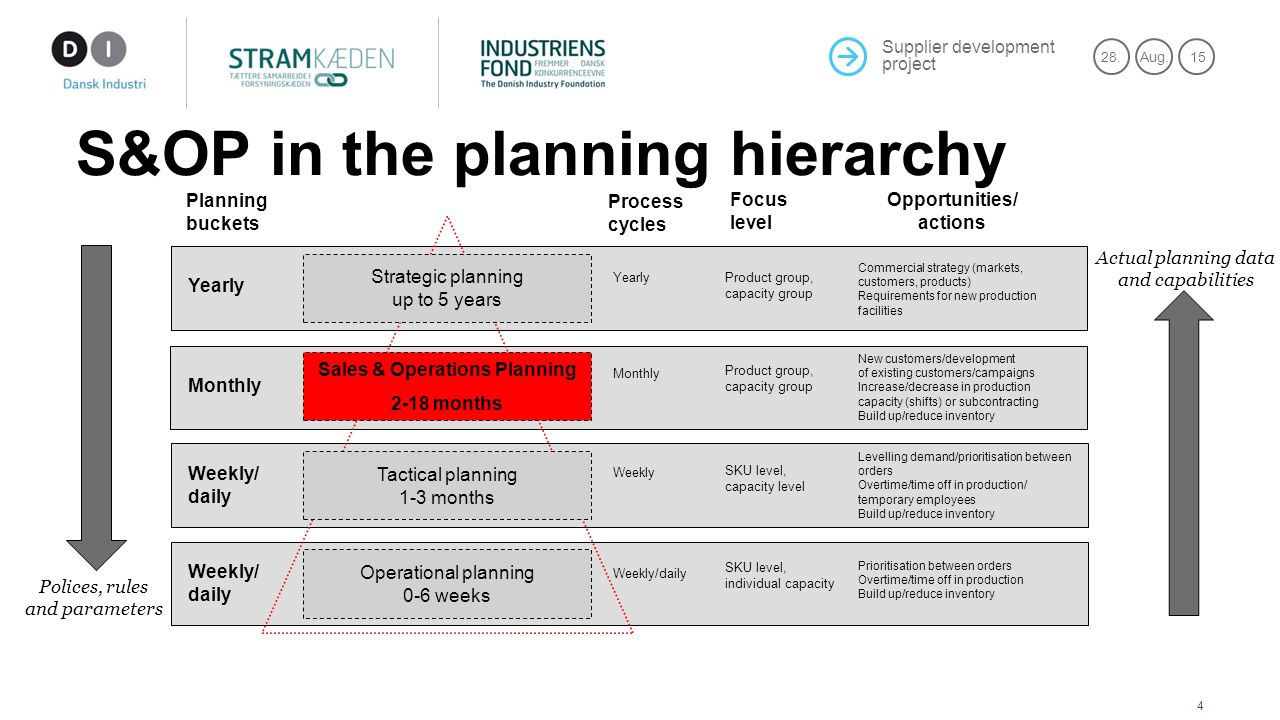

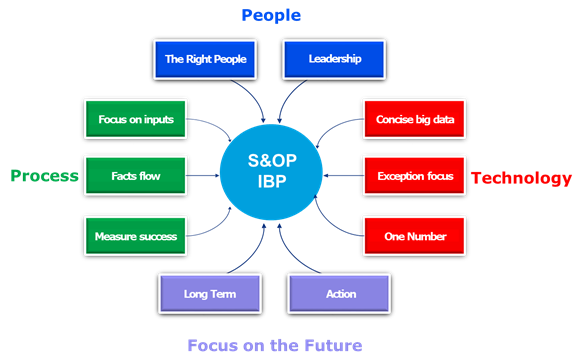

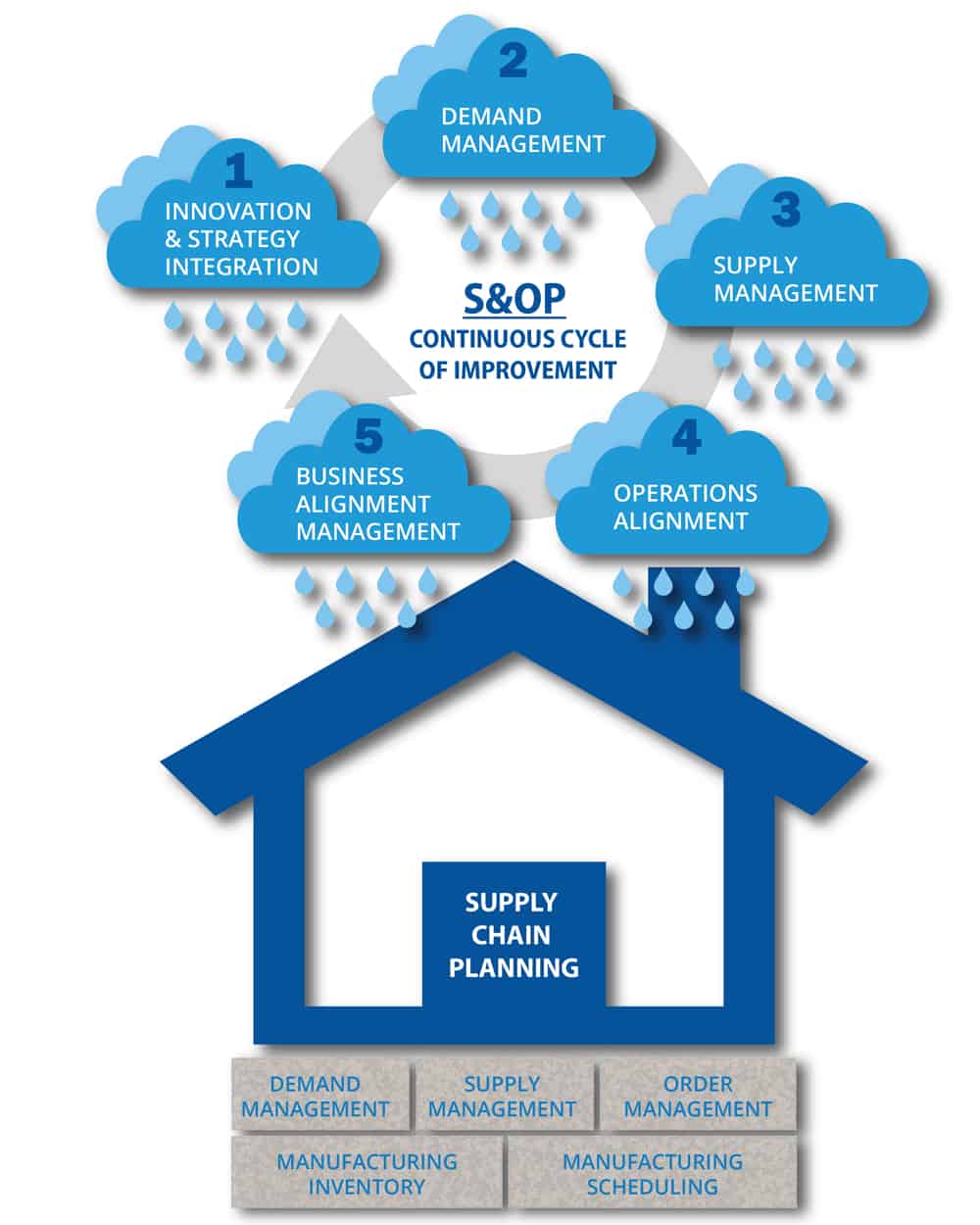

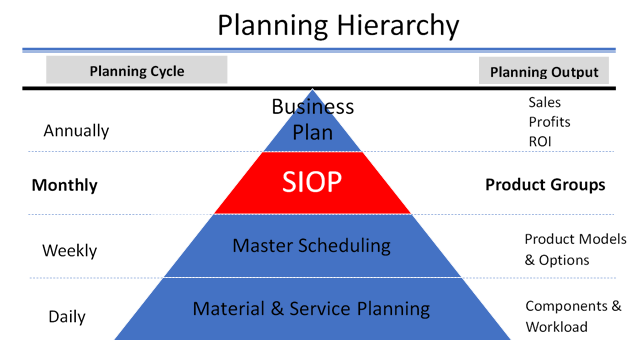

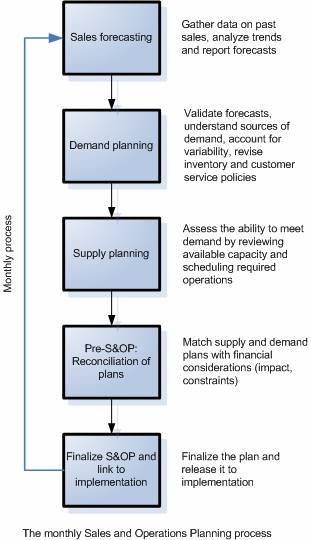

Operational planning – Rolling twelve months, reviewed monthly Translates tactical plans into specific objectives and confirms activities and timings through shortterm plans and execution Goal of S&OP process The primary goal of the sales and operations planning process is to facilitate the flow of information between demand and supply Standard SOP Process flow 22 34 70,9 Sales & Operations Planning (SOP) is a flexible forecasting and planning tool with which sales, production, and other supply chain targets can be set on the basis of historical, existing, and estimated future data Use SOP to streamline and consolidate your company's sales and production operationsS&OP is also referred to as Integrated Business Planning (IBP), particularly in the context of product management review and financial appraisal QAD DynaSys S&OP is part of the integrated endtoend QAD DynaSys DSCP solution Discover what else our Software can do Demand Planning, Distribution Planning, Procurement Planning, Production Planning

The importance of S&OP in Trends in personalization and fast shipping will require planning that goes beyond supply and demand It's , and the pressure is rising to move products through more channels in less time The challenge requires more careful planning Sales and operations planning (S&OP) has been talked about since the tool to support the S&OP process as they define it=2E So frankly, you can implement a system to support S&OP planning= in either R/3 or APO=2E As mentioned, the trick with R/3 is in = providing both a truly constrained and feasible Ops plans for= the business team=2E However, it can be done in R/3=2E Given this= Rather, I would agree with Oliver Wight's assessment that integrated business planning is about shifting the focus of S&OP beyond the supply chain team, so we can all benefit from the input of executive stakeholders while focusing on the needs of our customers A final note If you want to do as the Oliver Wight paper does and think of IBP as "Advanced S&OP," I think

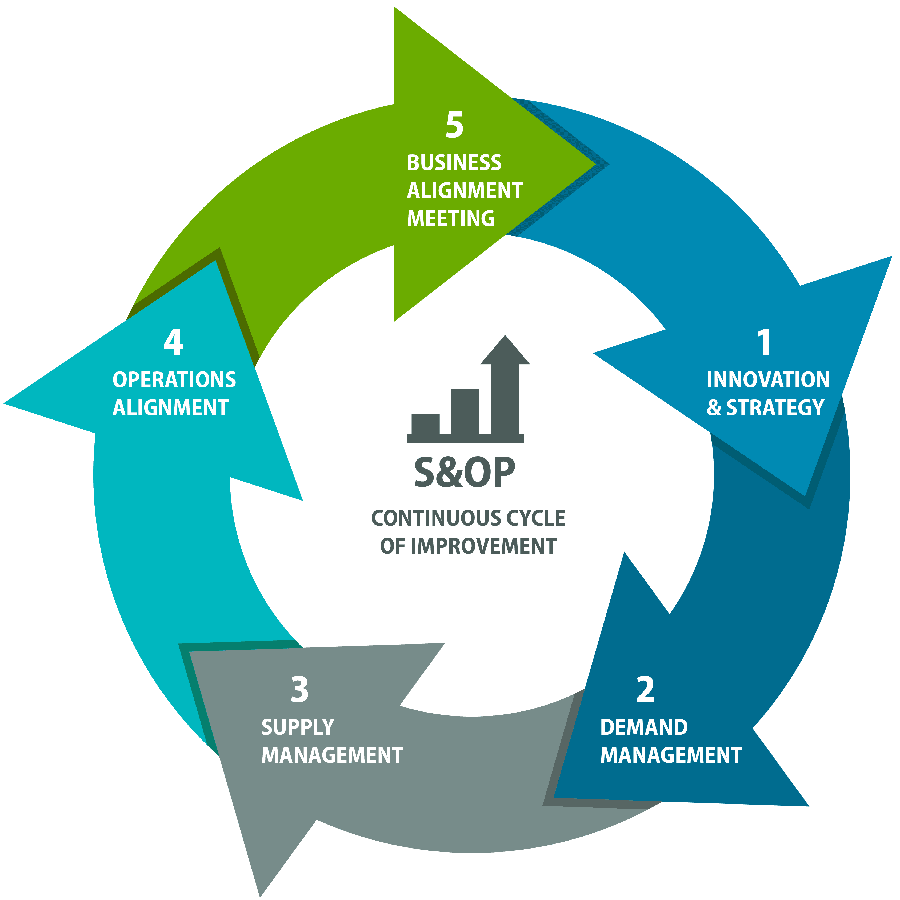

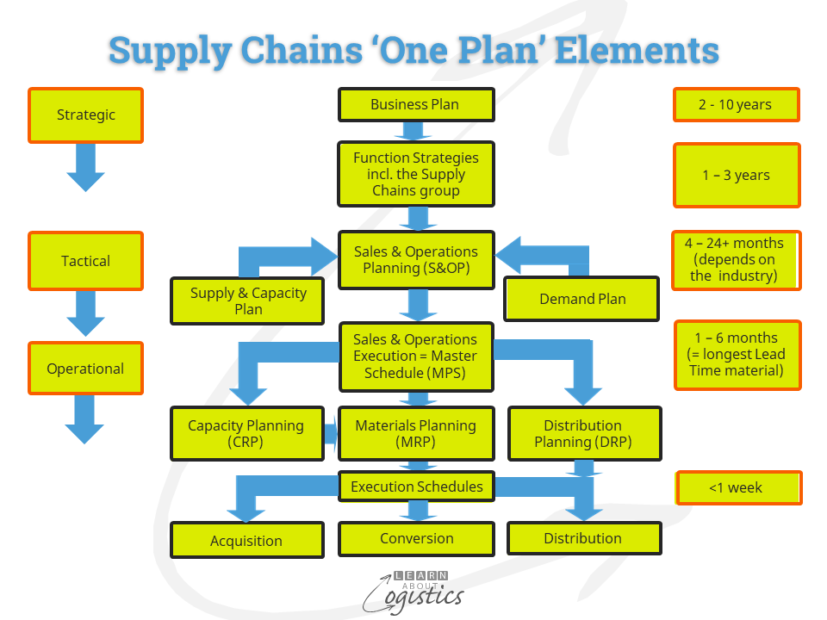

Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operational tactics in all departments 1 Sales & Operations Planning An Introduction Sales & Operations Planning An Introduction 2 S&OP Overview 3 The S&OP process was first developed in the1980's 1980's 1990's 00's Today S&OP evolved from supply chain execution activities such as MRP (material requirements planning) Today, S&OP is used across the Global 1000 4A weekly and monthly operations meeting S&OP is a process focused on the whole organisation ;

Ultimate Guide To Sales And Operations Planning S Op In 21

S Op Singapore Optimize Your Operation Planning Processes

The focus is on S&OP teams and companies who aspire to introduce the process to their organisations Sales & Operations Planning is the single process to engage all functions in creating aligned, forward looking plans and making decisions that will optimise resources so as to achieve a balanced set of goals It provides a single environment for S&OP is an oldline methodology that has been thoroughly updated to work in today's datadriven, technologyfocused manufacturing world And when you add technology to productions systems, you get a mountain of data to comb through, looking for ways to improve further Knowing which of the myriad metrics to measure is key to making the most of your S&OP The S&OP process in itself is the larger plan in which demand and supply planning play an integral part Many companies that implement demand planning and supply planning believe they have an S&OP process in place However, they often fail to fully utilize the collaborative benefits of manufacturing and inventory planning with demand and supply planning for

Integrating The S Op Process Go With The Flow Business 2 Community

Sales And Operations Planning Explorescm

The S&OP planning process should always be built on a realistic foundation, as the base line determines the trustworthiness of the S&OP plan That is why the operational plan should integrate towards IBP for S&OP (preferably via HANA Cloud Integration, HCI) HCI allows you to integrate data from your legacy system to IBP for S&OP applying translation rules for both master data andOnePlan S&OP is a demanddriven Sales and Operations Planning (S&OP) process focused on creating a centralized, dynamic, integrated business management process that promotes synergy across all key functions of the organization to provide a better plan Traditional S&OP is Static Respond to Market Changes in RealTimeAn S&OP plan is only as solid as the components that go into it One of the most important is the demand plan, which contains projected sales forecasts and other demandrelated data In order for the demand plan to capture the information that all consumers of the S&OP will need, those responsible for creating the demand plan would do well to address several key questions These

Implement The S Op Process For Supply Chain Success Learn About Logistics

The Fully Integrated S Op Of A Multi Site System In Supply Chain Download Scientific Diagram

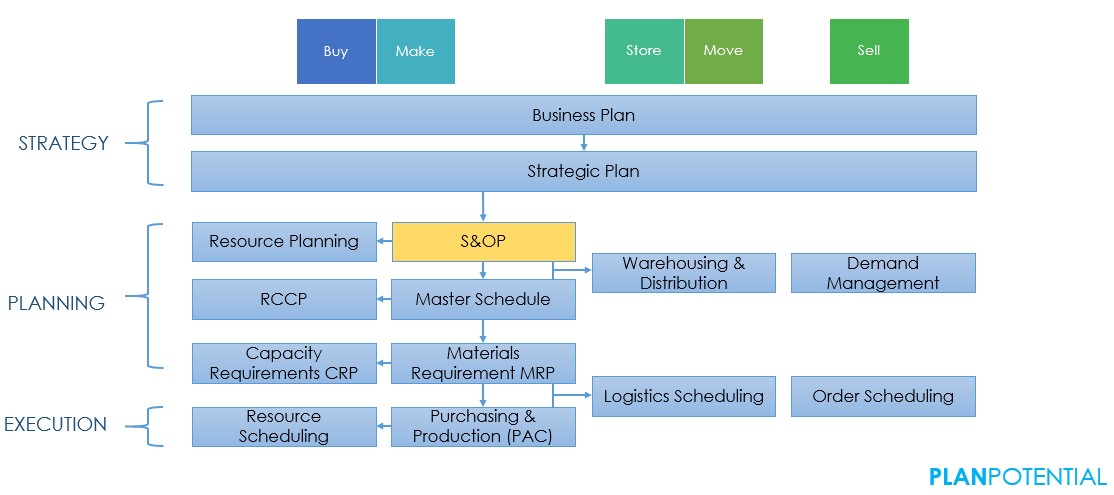

The business plan S&OP provides a structure for planning to address mediumterm situations; S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making It integrates demand, supply, operations, and financial planning into one game plan for businessS&OP develops a midrange plan to operations using input from top management The plan identifies key resources to achieve the firm's strategic objectives and goals, and is the basis of all subsequent material and labor resource decisions and for the master production schedule PUT S&OP INTO PRACTICE Imagine you are a senior supply chain manager at a smalltomedium

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations Planning Cycle Chainsequence Inc

Sales and Operations Planning (S&OP) Software takes into account all the various planning and monitoring processes that are necessary to run a worldclass supply chain This software can also help you take a crossfunctional approach to integrated business planning that unites all the moving parts across your supply chain with a shared focus to meet demand across markets, andSales and operations planning (S&OP) is an integrated planning process that aligns demand, supply, and financial planning and is managed as part of a company's master planning S&OP is designed and executed to support executive decisionmaking related to approving a feasible and profitable material and financial planSales and Operations Planning (S&OP) is a powerful decision making tool for business executives as well as line managers According to Tom Wallace, "S&OP enables the company's managers to view the business holistically and gives them a window into the future" Positive results that companies have gained from S&OP include hard benefits such as improved customer service

Sales And Operations Planning Mit Bross Partner

The Lost Link To Make Strategy Work Sales Operations Planning S Op Strategok By Javier Gonzalez

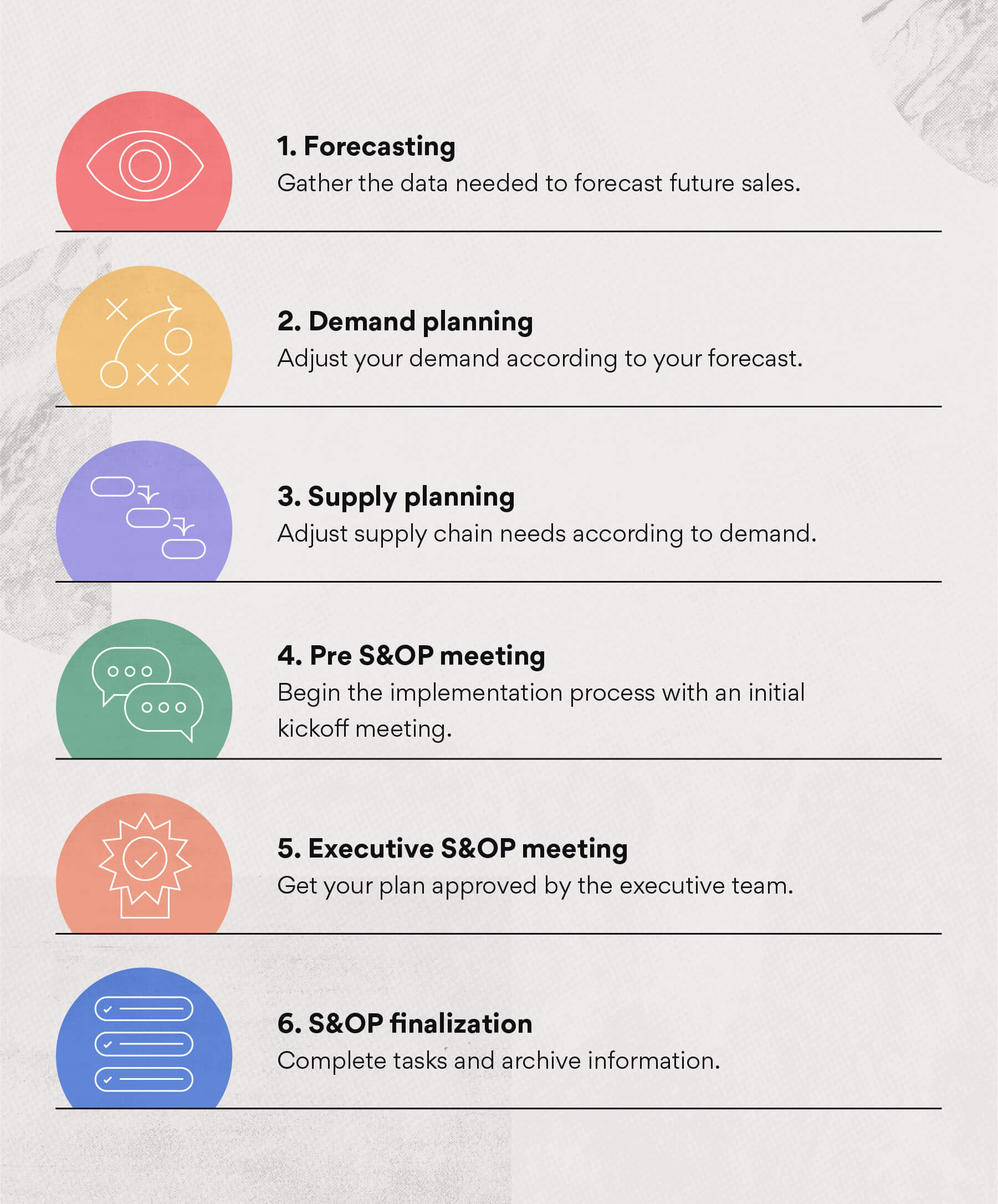

S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change In practice, it is called a replanning process S&OP is owned by the GM or CEO It is a crossfunctional process and includes all the functions of the company Correctly implemented, it is a demand and strategydriven processAnaplan Sales and Operations Planning (S&OP) unifies all relevant business units into one cloudbased, connected platform Integrate plans and signals from sales, finance, production, marketing, and supply chain Make betterinformed decisions that maximize profitability and convert change to your advantage Sales and Operations Planning use cases Created with Sketch ScenarioS&OP plan finalization and release The final step of the S&OP process is to present the optimized, finalized plans to senior management so they can be approved and released for implementation Screenshot of sales and operations planning software S&OP integration with other cloudbased systems Sales and operation planning is only as good as the data that it is built on When data is

S Op More Important For Planning New Era Supply Chains Learn About Logistics

Sales And Operations Planning S Op

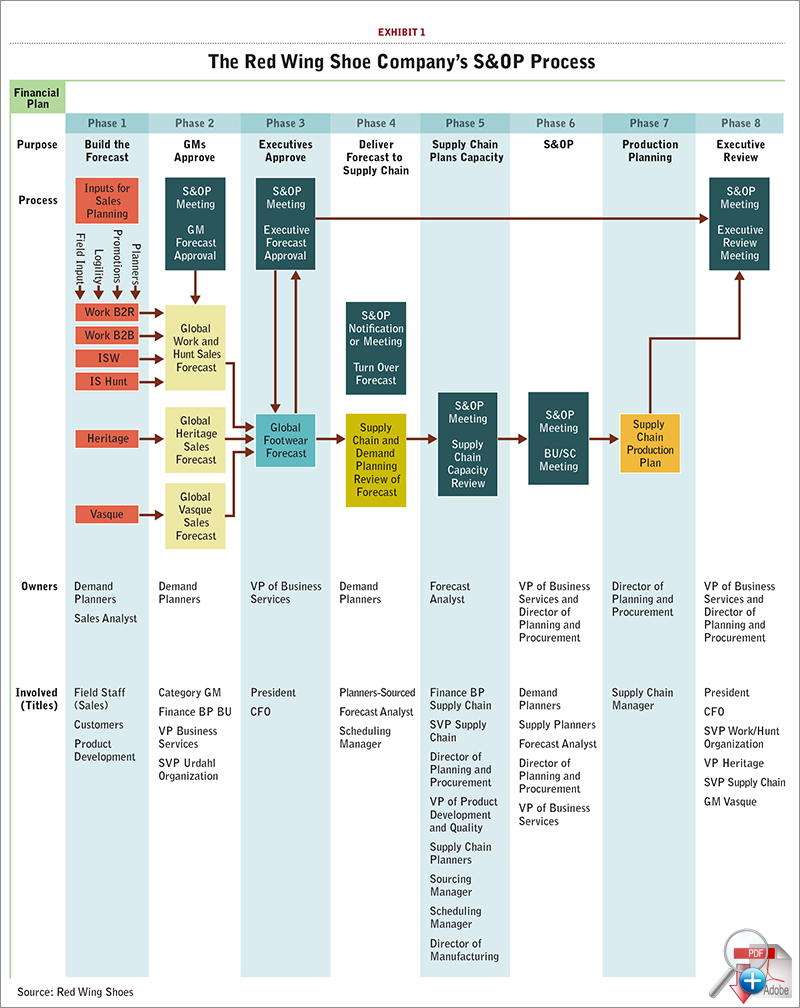

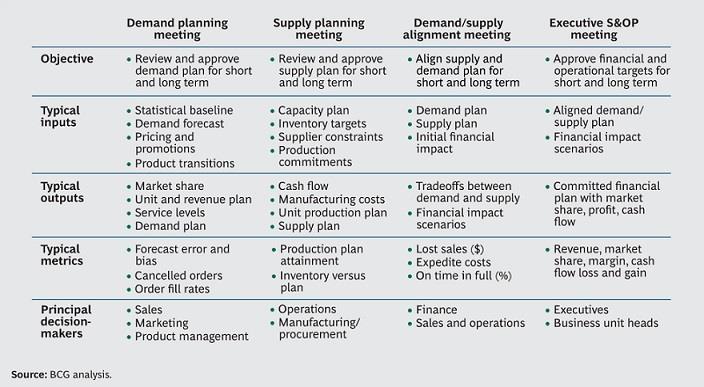

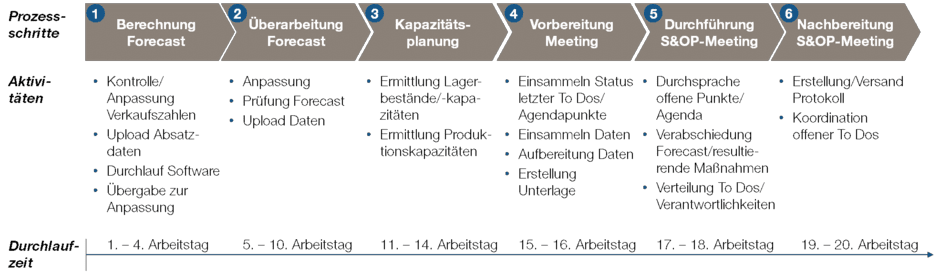

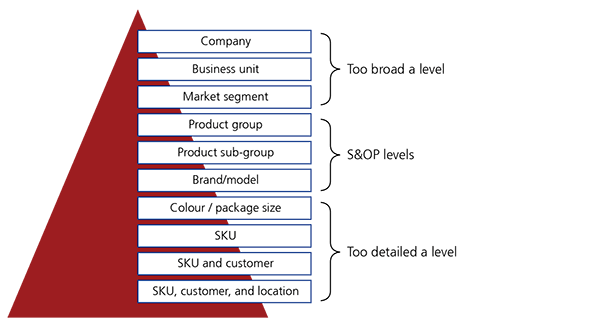

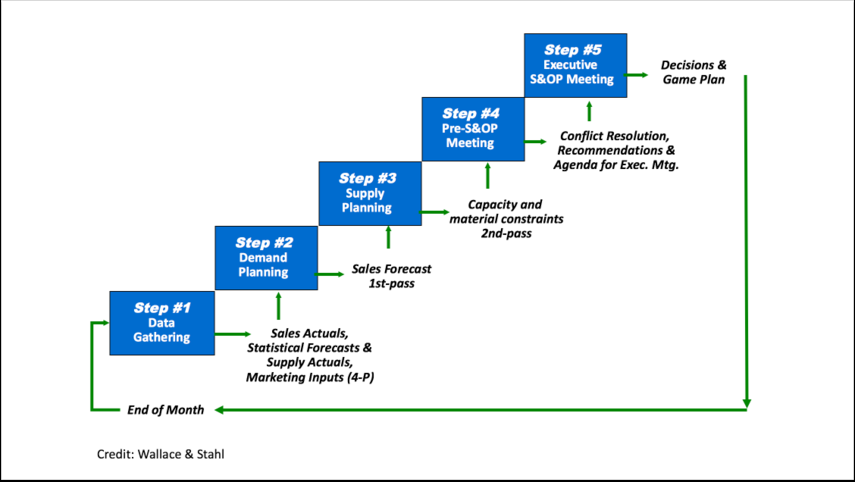

To plan the product group in standard S&OP, use the menu path, Logistics > Production > SOP > Planning > For Product Group > Create, or use Transaction MC81 The figure above shows the initial screen of the roughcut plan for the product To ensure the S&OP plan is as effective as it possibly can be, keep these sales and operations planning best practices in mind 1 S&OP Should Start at the Top Your sales and operations planning efforts will only be successful if company leaders buyin and lead the charge Without executives, the process will get bogged down as lowerlevel employees continually seekThe Sales and Operations Planning (S&OP)1 process is well known and understood in the world of supply chain management In most companies, the monthly S&OP meeting brings executives from all major operational departments – sales, marketing, materials/procurement, manufacturing, transportation, and finance – together to determine how best to manage company resources to

Sales And Operations Planning A Project Manager S Guide Asana

Huge Step To Achieve Collaboration Within S Op Supply Chain Movement

Sales & Operations Planning ( S&OP) is the process by which we bring together all the plans for the business (Customers, Sales, Marketing, Development, Manufacturing, Sourcing, and Financial) into one integrated set of tactical plans S&OP gives management the ability to direct its business to achieve a sustainable competitive advantageTherefore S&OP is an input to budget updates, but should not be constrained by budgets; Although S&OP planning can be extremely strategic, involving seniorlevel executives and pivotal decisions, most companies focus on the transactional level and, to a lesser extent, the operational level Yet all three levels are integral to effective planning Companies that understand this can gain an information advantage Since decisions made at one level can affect the other

1

Sales And Operations Planning A Project Manager S Guide Asana

It's time to evolve your sales and operations planning (S&OP) This eBook looks at why scheduled decisionmaking is becoming outdated and the three foundational capabilities that will power your S&OP processes into the future Powering the future of S&OP 3 capabilities to fuel your journey The speed in which scenarios can be created and analyzed has gone from 24–48What is Sales & Operations Planning (S&OP)?Sales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and production The practice usually revolves around a monthly process starting from the sales forecasts and ending with quantified production plans

Supply Chain Graphic Of The Week The S Op Process

What Are The Basic Elements Of The S Op Process Quora

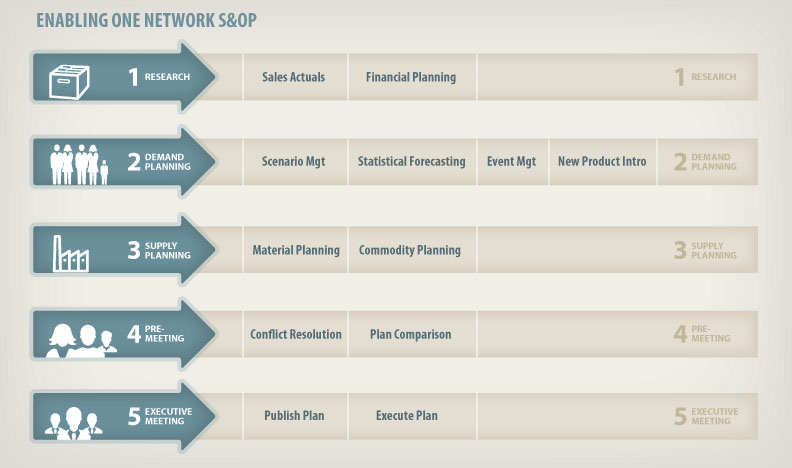

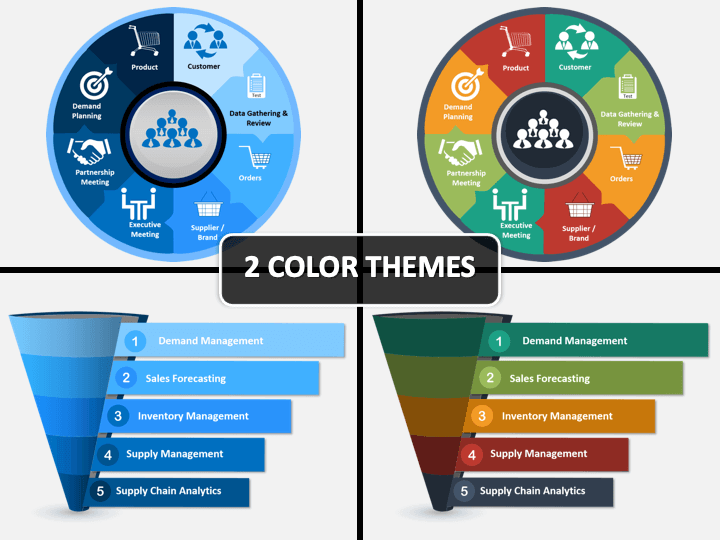

S&OP Demand Planning Data Gathering & Setup (Analysis, Exception Reporting, Statistical Models, Data Aggregation) Routine Forecasting Cycle (Demand Change Reviews, Sales History and Future Forecast Adjustments, Unconstrained Forecast) Monitor & Improve Forecast Accuracy (Forecast Accuracy KPI, Forecast Value Added from Business Intelligence) Sales &Sales & Operations Planning (S&OP) One Network's unique Sales and Operations Planning (S&OP) solution is built on the Real Time Value Network, enabling subscribers to coordinate strategic and tactical planning across all internal operations and key trading partners, from the point of consumption to raw material suppliers VIEW NOW The S&OP Supply Plan shown in the 5 Section Sheet is a clear statement of the mission The Master Scheduler can see the objective clearly, and they can set up the build plan to match the volume This doesn't mean that the Operation will hit the desired output, but the volume is synchronized to the S&OP Supply Plan, and any variance to the plan will translate into

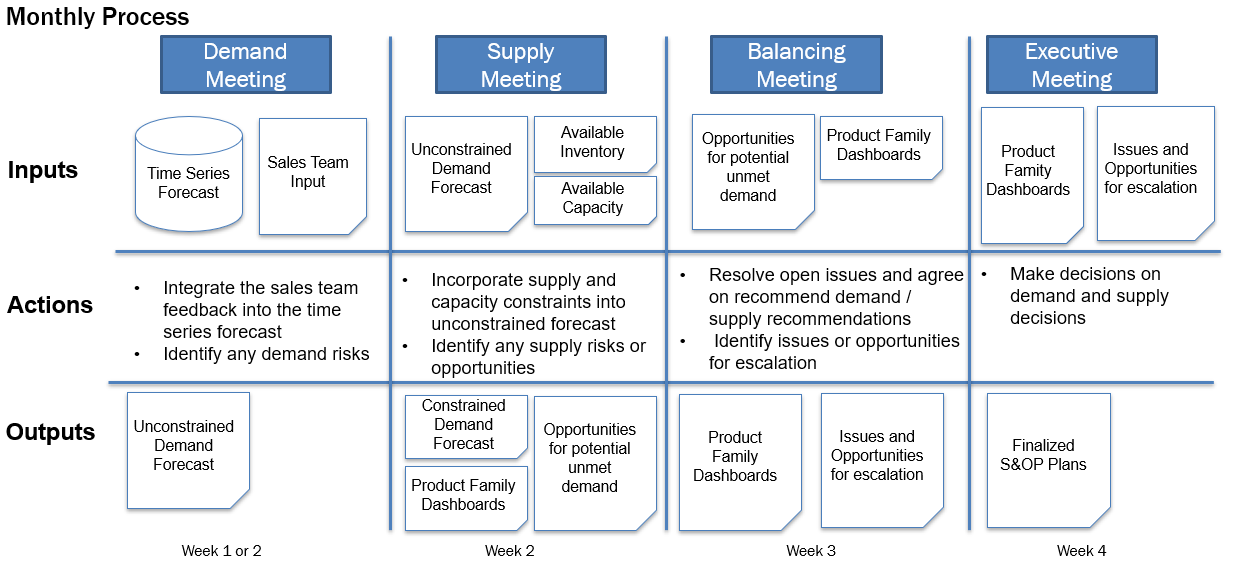

Sales Operations Planning Consulting Supply Velocity

Ibp Cnt

S&OP Implementation For Beginners 80% of success in S&OP implementation depends on the people element Antonio is in charge of Supply Planning at Sibelco, a global supplier of minerals and raw materials Here, Antonio leads the S&OP process and Supply Chain Management initiatives, including inventory management, distribution management, data S&OP, or sales and operations planning, is a management process that focuses and synchronizes the various teams of an organization in order to ensure supply production matches with demand In a small business, this is typically a very narrow process in which they really only have to look at inventoryEffective S&OP planning depends on the input But it's important to keep in mind that in order to move forward with a monthly S&OP plan, you must determine at which point in the month edits to the demand plan will no longer be allowed Use the following process overview as a template to define roles, responsibilities, and timing of each step after the close of each month The steps

Sales And Operations Planning S Op Mit Sap

Planning And S Op Processes Ops Manager Now

Sales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1 S&OP (Sales and Operations Planning) or SIOP (Sales, Inventory and Operations Planning) is a well known supply chain planning process, yet not all supply chains have embraced Sales and Operations Execution (S&OE) As we all know, what you plan for and what actually happens can frequently be two very different things The role of S&OE is to capture the S&OP is an enterprise wide business planning process that can only be effective and sustainable when it is supported by the right mindset and behaviours Individuals and teams with a superior mindset will increase S&OP effectiveness and are proven to perform better and show increased wellbeing However, it is unlikely that there is a critical mass of these behaviours in

Sales And Operations Planning S Op 101 Smartsheet

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Smoother Execution Through S Op Logistics Management

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Sales And Operations Planning Relex Solutions

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

Chapter 14 Aggregate Sales And Operations Planning Lecture

How S Op Improves Your Organization Tmc Fr

S Op More Important For Planning New Era Supply Chains Learn About Logistics

What Is S Op How S Op Works Demand Planning Com

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Extended Sales And Operation Planning Es Op Customer And Supplier Ppt Video Online Download

The Sales And Operations Planning Process In The Context Of Various Download Scientific Diagram

Achieve Excellence In Sales And Operations Planning Sapinsider

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Sales Operations Planning S Op Sap Library Sales Operations Planning S Op

Oracle Demantra Sales And Operations Planning User Guide

Sales And Operations Planning The How To Handbook Wallace Thomas F Stahl Robert A Amazon De Bucher

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sales And Operations Planning S Op Logistiikan Maailma

Sales Operations Planning Why Is S Op Important

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Integrated Business Planning Ibp S Op Evolution Agile Innovation

S Op The Evolving Supply Chain Lifeline Supplychainomics

What Is S Op How S Op Works Demand Planning Com

Sales Operations Planning Lieferkette Besser Abstimmen

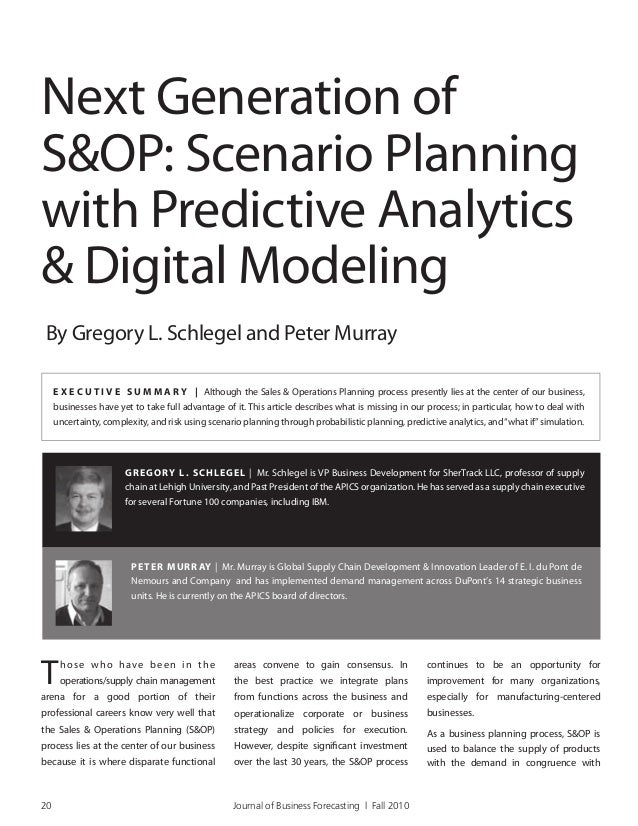

Next Generation S Op

Sales And Operations Planning S Op Transform Your Business

What S Holding The S Op Process Back Part Two Establishing A Business Efficiency Planning Process That Works Chainalytics

1

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

S Op Sales Operations Planning During And Post Pandemic Like Covid

Common Sales And Operations Planning Myths Supply Chain 24 7

What Is Sales Operations Planning Supply Chain Minded

S Op Sales And Operations Planning Acronym Stock Illustration

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Pdf Sales And Operations Planning Part I The Process Semantic Scholar

1

S Op Planning Services Chainsequence Inc

From S Op To Ibp The Discussion Continues

Sales And Operations Planning Report Do You Get Surprises

Sales Operations Planning Scpi

1

Achieve Excellence In Sales And Operations Planning Sapinsider

Scielo Brasil A Case Method For Sales And Operations Planning A Learning Experience From Germany A Case Method For Sales And Operations Planning A Learning Experience From Germany

Successful Change Management Adds Value To Your S Op Process Implement Consulting Group

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

S Op And S Oe A Symbiotic Relationship

S Op In Der Chemieindustrie Hoveler Holzmann

Was Ist S Op Absatz Und Produktionsplanung Entstehung Und Prozess

Sales Operations Planning Engagement Model Tvo Maine Pointe

Sales And Operations Planning Relex Solutions

Wir Optimieren Ihr Sales Operations Planning Www Ak Online De

Sales Operations Planning S Op And Sales Operations Execution S Oe Engineering Usa

Sales And Operations Planning S Op Logistiikan Maailma

Sales And Operations Planning Powerpoint Template Sketchbubble

The Fully Integrated S Op In Supply Chain Planning Context Download Scientific Diagram

Improving Profitability With Sales Operations Planning Magellan Consulting Group

Getting To Grips With Sales And Operational Planning Bloor Research

Who Should Own Sales And Operations Planning I Kinaxis

Sales And Operations Planning Relex Solutions

Scm Awareness S Op Process Planpotential

Sales And Operations Planning S Op In 14 Steps Gestiona Band 0 Soler Garcia David Pena Andres Cristina O Donnel Henry Amazon De Bucher

S Op Software Sales And Operations Planning Qad Dynasys

Achieve Excellence In Sales And Operations Planning Sapinsider

What Is S Op How S Op Works Demand Planning Com

S Op Sales And Operations Planning Acronym With Marker Business Concept Background Canstock

Sales And Operations Planning Process Self Assessment

Lean S Op Sales Operations Planning Four Principles

S Op Singapore Optimize Your Operation Planning Processes

23 S Op Ideas Sales And Operations Planning Supply Chain How To Plan

Sales And Operations Planning Supply Chain Business Solutions

Fsales Operations Planning

Sitmi Science Industrial Technology And Management Intelligence S Op Sales And Operations Planning Process Flow Simple And Quick Explanation Of Each Steps Facebook

Group50 S Sales And Operations Planning Services By Calling 909 949 90 Emailing Info Sales And Operations Planning Change Management Capacity Planning

Software For Sales Operations Planning In Europe Supply Chain Movement

Sales Operations Planning S Op Demand Planning Cargo

Sales And Operations Planning Business Forecasting Taruna Nagpal

What Is One Plan S Op Arkieva